Making Sense of Makerspaces

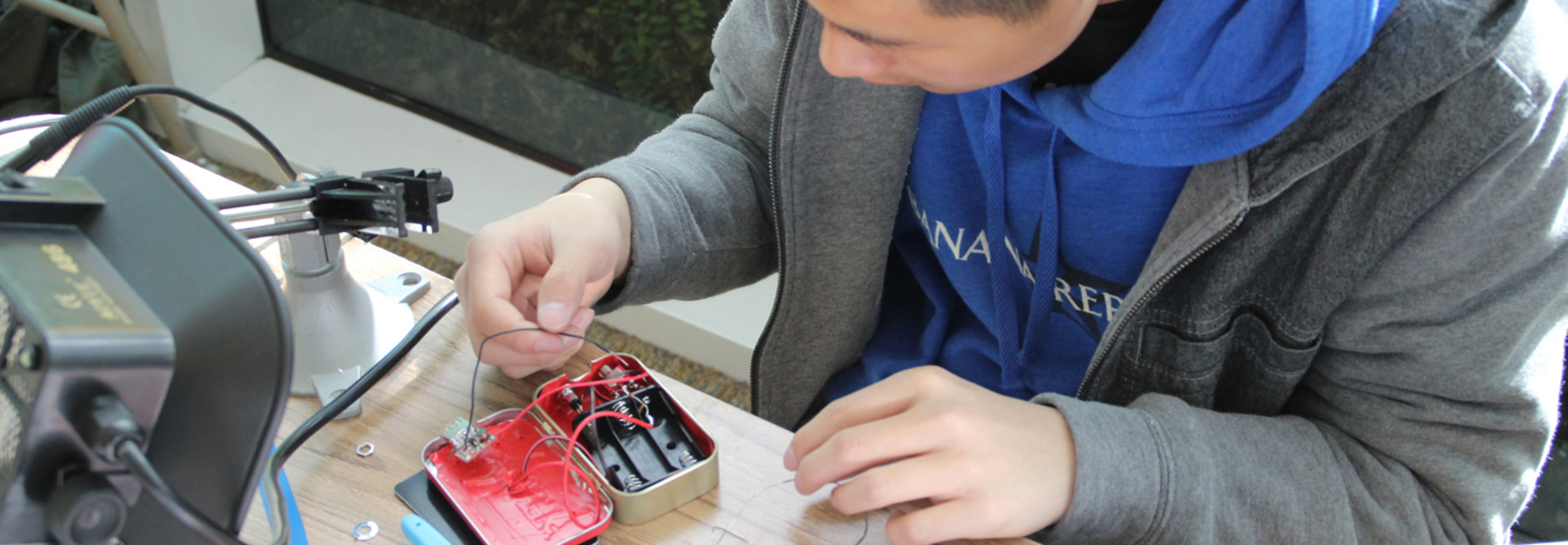

Many school leaders carve out room for "makerspaces," which encourage hands-on learning through the use of tools — anything from glitter and glue to homemade circuits, 3D printers and computer-aided design (CAD) software.

But not Aaron Vanderwerff. "The whole school should be a makerspace," insists Vanderwerff, Creativity Lab and science coordinator for the K–12 Lighthouse Community Charter School in Oakland, Calif. "We don't want kids to think that making things is something you have to do in a separate area."

Tools of the Trade

The makerspace toolbox includes technology, of course, but Vanderwerff's students also rely on sewing, soldering and woodworking to learn. He's open to any method that helps students more deeply understand concepts, noting that he recently helped students studying electricity create paper circuits that could be used in greeting cards, for example.

Alex Podchaski also has started creating a makerspace at Oak Knoll School of the Holy Child in Summit, N.J.

The number of people who attended Maker Faires in the San Francisco Bay Area and New York City in 2013

SOURCE: Maker Media

According to Podchaski, director of technology, a sixth-grade student studying ancient Egypt recently used the makerspace's MakerBot Replicator 2X experimental 3D printer to design, print and decorate a cosmetic case to resemble an archeological dig discovery. Other students have used the technology to print sarcophagi, mummies and even pyramids.

"The teacher makes the material lively and interesting," Podchaski explains. "Technology then can provide additional meaning to what goes on in class."

It's important for educators to understand the impact that makerspaces can have on the community at large, adds Sarah Boisvert, founder of FabLabHub, which helps teachers launch digital fabrication makerspaces. "Makerspaces foster innovation across industries in entrepreneurship, design, art, manufacturing and education," she says.

During Black History Month, for example, students used a fab lab at one high school to design and fabricate quilts. "They not only learned the history, but also incorporated math and CAD" — skills that are essential for economic growth in markets such as prosthetics and dental molds, Boisvert says.

Vanderwerff couldn't agree more. "We've been teaching STEM in a traditional way for a long time," he says. "If we integrate what we're doing in the maker world, we are sure to attract more students."