Making the Most of Power and Cooling Management

With an elevation of 800 feet above sea level, Cedar Hill is the geographic high point of Dallas County, Texas. As a result, the area is prone to frequent lightning strikes and, subsequently, frequent power outages. But there’s no downtime at the Cedar Hill Independent School District’s data center, where modern power and cooling management systems keep the energy flowing.

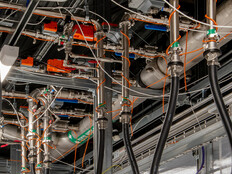

By turning to the latest generation of uninterruptable power supply (UPS) units, power distribution units (PDUs), in-row cooling systems and other capacity management technologies, Cedar Hill ISD (and other districts like it) not only has solved disruption challenges, but also has netted budgetary and energy-efficiency rewards. Rapid advances in server technology, along with the density of machines enabled by virtualization, have made data center power and cooling a top-of-mind issue for IT and facilities executives in organizations of all types and sizes, says Jed Scaramella, a research manager at IDC.

That’s certainly been the case for Cedar Hill ISD’s IT team. “We needed technologies that were capable of accommodating the power outages we experience in our area,” says Neil Bolton, network analyst for the 8,200-student district, which encompasses 13 campuses and two administrative buildings in suburban Dallas. The opportunity to eliminate such disruptions came when district and city government officials decided to construct a new, shared data center. The collaboration made it possible to design a power and cooling management infrastructure that focused on meeting new needs “without concern about whether our environment could support it,” Bolton explains. “All we had to do was slide our servers in.”

The turnkey solution they chose includes an APC InfraStruxure modular PDU system for the server racks; a scalable APC Symmetra PX UPS; an APC Cooling Distribution Unit; several APC InRow RC units; KVM switches housed in APC NetShelter VX and SX rack enclosures; collateral devices; and management software. According to Bolton, the solution tied directly into the data center’s cooling system, eliminating the capital expense of dedicated cooling and saving tens of thousands of taxpayer dollars in the process. Thanks to the system’s efficient cable management features, “we no longer have 30 feet of cable stretching across the data center,” creating even more savings, he adds.

The setup also makes Cedar Hill ISD greener. “APC’s hot-aisle containment system saves 50 percent on cooling versus a traditional room air conditioner,” Bolton says. “And the management panel, which we can access on- or offsite, allows us to control the health of the entire data center or drill down to individual components.”

Even APC’s preventive maintenance agreement, which includes biannual onsite checkups, helps conserve resources. “Technicians identify and fix issues before they become problems,” Bolton explains. “As a result, we’re proactive throughout the whole life of our solution.”

The APC system also positions Cedar Hill ISD for future sustainability efforts. “We can go virtual and, depending on the next wave of technology’s evolution, we can go back,” Bolton says. “It has the flexibility to grow with us.”

Generator Assist

The story is the same 1,000 miles to the north, where the Mattawan Consolidated School District experiences weather-related events that can knock out power for days.

To keep its Cisco Systems–enabled computing network and Voice over IP phones operational, the four-school district in southwest Michigan installed a Liebert Nfinity scalable UPS in the main data center and Liebert GXT units in the wiring closets of all eight buildings on campus. “We needed solutions that would integrate smoothly with our generator,” explains Information Technology Director Peter Poggione. “It can be 10 to 15 seconds before the generator takes over, but that’s a really important 10 to 15 seconds for keeping the network, phones and air conditioning running.”

SOURCE: “Improving Power and Cooling Efficiency in the Datacenter” (IDC, June 2010)

The Liebert equipment fulfills those critical needs seamlessly, Poggione adds. “When we experienced a generator hardware failure in March 2010, the Nfinity unit kept our data center running for two hours while we took corrective action,” he recalls.

Poggione also appreciates the web-based configuration and monitoring utilities. “We receive notifications for [power] quality issues,” he explains. “This is something you wouldn’t necessarily notice in the course of a day, but it can be really detrimental to your equipment over the long term if it isn’t monitored and corrected.”

Product longevity is equally important, especially when money is tight. “We needed a solution with a 10-year refresh cycle,” Poggione continues. “With the Liebert equipment, we’re on pace to make our lifecycle goals.” The setup also enhances districtwide emergency preparedness. “When there’s a disruption, I know before anyone else,” he says. Nfinity even provided a boost to the district’s VMware-enabled virtualization efforts, making it possible to run “about 30 virtual Windows and Linux machines on just four physical servers.”

Sized to Grow

Standardization also solved many of the power and cooling management challenges plaguing the 12-school DeKalb Community Unit School District #428 in Illinois.

“In the past, we deployed products from a variety of manufacturers,” explains District Technology Manager Ben Bayle. “When we began planning for our new high school, which opened last August, we decided that standardizing districtwide would improve efficiency and promote vendor rapport.”

Bayle and his team appreciated Tripp Lite’s known reliability and the fact that it proposed a system “that was sized to grow,” he says. “Scalability was especially important because we expect 20 percent growth over the next few years in the face of ever-shrinking budgets.” Having the ability to manage all components centrally was equally important because the district’s buildings are spread over a wide suburban area, Bayle adds.

Although construction of the high school stretched the district’s power and cooling management deployment over a two-year period, Tripp Lite personnel “saw us through from beginning to end,” he says. “They were cost-effective, yet thorough. And everything went off without a hitch.”

Power to Spare

Maximize today’s power and cooling solutions by following these tips:

- Calculate (don’t estimate) exact power needs. Be sure to include quality and duration in your analysis.

- Document and communicate changes. This is especially important to do when construction projects span years because new models of networking gear, such as switches, can require a cascade of adjustments by all parties.

- Delay lighting installations when constructing (or renovating) data center facilities. Installing PDUs first makes it easier to configure the light fixtures to shine between the aisles.

- Make monitoring routine. This will ensure that you get the most out of your equipment.

- Negotiate full-service maintenance agreements. Next-day air is too late when you’re trying to keep the core of your operations running.