Review: Dremel DigiLab 3D45 3D Printer Makes Creation Fast and Easy

Dremel, a company known for its award-winning rotary power tools, has built a 3D printer that deserves a place on today’s modern campus. In makerspaces and classrooms, instructors in varied disciplines are integrating these devices into course assignments. Students of music theory have created 3D models of sound waves, while 3D replicas give geology students a new way to understand fossils.

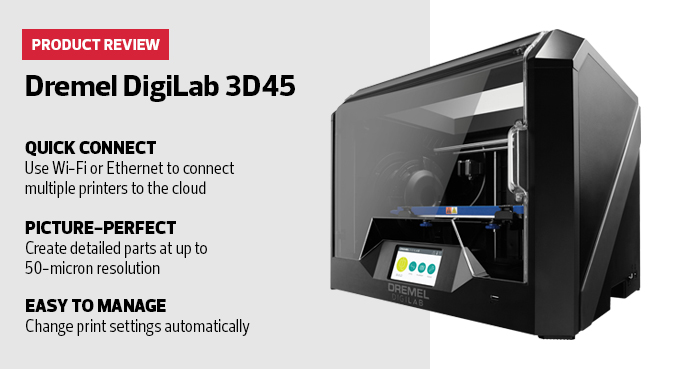

The DigiLab 3D45 is a network-enabled 3D printer that features a heated bed, fully enclosed build chamber and its own cloud-based printing solution. The unit looks and feels solid, with tight hinges on the lid and front door. The enclosed build space is a plus for printing materials that require a temperature-controlled environment, such as ABS or nylon. A glass build platform, which can reach 100 degrees Fahrenheit, helps the filament adhere to the surface during printing.

MORE FROM EDTECH: See how one university uses 3D printers to bring curricula into the digital age.

Quick Setup Puts Dremel 3D Printer to Work in Minutes

A 5-inch, full-color touch screen on the front displays a menu for controlling the printer. From there, users can get to all the controls, such as leveling or changing the filament, as well as other tools. The filament spool mounts on the inside of the printer and can be easily accessed through a side panel.

Dremel materials are tagged for radio-frequency ID, so the printer automatically detects the type of filament and configures the appropriate temperature settings for that material. The filament then feeds up a tube and into the direct-drive extruder.

Initial setup was quick and easy. In fact, with some supervision, I tasked two students with unboxing and setting up the printer, and in less than 15 minutes, we were printing our first test object. The setup takes the user through the leveling process, during which a small sensor drops down from the extruder to detect the height of the build plate. The screen indicates if any of the leveling adjustment knobs need to be turned and which way to turn them. The knobs, located in the front part of the build plate, are easy to manipulate.

Dremel Cloud Solution Lets Users Print 3D from Anywhere

During testing, I printed several objects, some in high resolution and others in standard. Print quality was great, with no imperfections in any of the objects. One of my students designed a replacement part for a kitchen drawer using Tinkercad by Autodesk. He printed the part using PLA — a biodegradable thermoplastic polyester made from renewable resources — and it came out well.

The machine itself is quiet. The printer includes a carbon filter and a fan, so it filters out any potentially volatile organic compounds that might be of concern. A flash drive is included and can be plugged into the USB port. With an Ethernet port and built-in Wi-Fi, the printer can connect to any network and be accessed through the Dremel Print Cloud solution.

MORE FROM EDTECH: Check out three ways universities can use 3D printers in innovative ways.

Inspire Creativity and Teamwork with a 3D Printer Challenge

Teamwork makes the dream work. That’s what my middle school football coach told me. It was true then, and it’s true today, especially in a modern classroom. Instructors looking for a project that incorporates the use of a 3D printer and teamwork should check out the Dice Game Challenge.

The challenge tasks students with using the engineering design process to create a new dice game that could revolutionize the toy industry. They work together to build their product and present their ideas to the class.

As a judge, the instructor is asked to play and rate each product fairly, using a rubric — for example, awarding a maximum of 5 points for each of the following categories: introduction, product explanation, graphics, marketing strategy, directions and presentation.

Any physical game elements, such as game pieces or dice, must be designed and 3D printed. Dice do not have to be traditional, six-sided dice, nor do they need to have dots. Students have a lot of fun with this project. Some of my teams went above and beyond, creating a board game complete with a game box one might expect to buy at the store.

Dremel DigiLab 3D45

Build Volume: 10x6x6.7 inches, 402 cubic inches

Materials: Nylon, Eco-ABS, PLA

Operating interface: 5-inch, full-color IPS touch screen

File types: STL, OBJ

Build platform: Semiautomatic leveling