3 Ways Universities Expand 3D Printing Innovation

On some college campuses, a 3D printer might be easier to find than a regular printer.

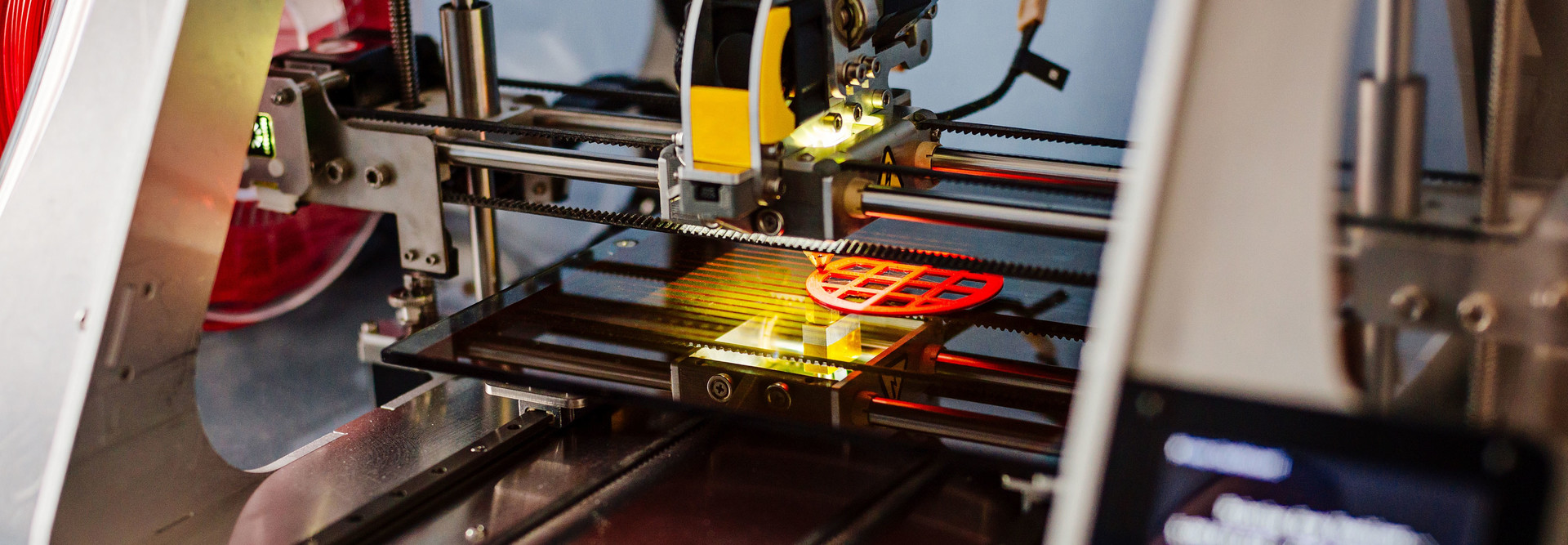

Universities and community colleges have embraced the maker movement — which emphasizes learning through doing — and have added 3D printers to everything from manufacturing courses to the visual and performing arts.

With such a ubiquitous presence in higher ed, institutions have led innovation and advances in 3D printing that could have implications throughout all industries.

SIGN UP: Get more news from the EdTech newsletter in your inbox every two weeks!

1. Researchers Seek to Optimize the 3D Printing Process

As more 3D printers become available for academic use, university researchers have explored how they might be able to make the devices run more efficiently.

For example, Massachusetts Institute of Technology researchers created a desktop 3D printer that is 10 times faster than those currently on the market, Campus Technology reports. To move filament in printers faster, the MIT team replaced the typical pinch-wheel design — where two wheels turn together to pinch filament and pull it toward the printhead — with a screw design in the printhead that turns and pulls textured filament.

With the traditional pinch-wheel design, print speed couldn’t be increased or the wheels would lose traction. By changing up the movements and adding texture to the filament, Campus Technology reports that this no longer happens.

The MIT researchers also used a laser to heat filament faster and redesigned the frame of the printer to allow for faster movement. A faster 3D printing process could have a huge impact on industries that rely on them.

“If I can get a prototype part, maybe a bracket or a gear, in five to 10 minutes rather than an hour, or a bigger part over my lunch break rather than the next day, I can engineer, build and test faster,” says Anastasios John Hart, an associate professor of mechanical engineering at MIT, who spearheaded the research, in an MIT News release.

Another research team at MIT even explored the possibility of printing models using the organic compound cellulose to make 3D printing more environmentally friendly and cost-effective.

2. Better Monitoring Can Boost Printer Security

University researchers have also explored the vulnerabilities of 3D printers and how users can identify if a bad actor has tampered with a 3D printed object.

A research team from Rutgers University-New Brunswick and the Georgia Institute of Technology barcoded filament with gold nanoparticles and then used chemistry techniques to map the 3D model and make sure nanoparticles were where they were supposed to be.

“If the location of the nanoparticle is different from the predicted location, then one can assume the model has been tampered with,” Mehdi Javanmard, an assistant professor of electrical and computer engineering at Rutgers-New Brunswick, tells EdTech.

The research team also used motion and sound tracking technology to identify deviations in the desired movement of the printhead.

3. 3D Printing in Academia Allows Students to Innovate, Give Back

As 3D printers make their way onto campuses, students are finding ways to use the tools for more than just manufacturing. Innovative students across the country have stepped up to help people in their communities by making prosthetics.

At George Mason University in Fairfax, Va., five bioengineering students created a custom prosthetic arm to help a 10-year-old girl continue to pursue her passion of playing the violin.

Students at Cuyahoga Community College (Tri-C) leveraged their studies on additive manufacturing to create prosthetics that allowed disabled veterans to once again experience simple pleasures, like turning the page in a book, reports Cleveland.com.

While these projects stand alone as humanitarian acts, they are also allowing students to get a better taste of manufacturing.

“It’s one thing to assign a project that is just a figment of my imagination, but I figured that it would be more impactful to test the students using problems that actually existed out in the real world,” says Tri-C instructor Maciej G. Zborowski, in the article.