Colleges Prep Students for Additive Manufacturing Careers

At Auburn University in Alabama, students can augment a traditional four-year program with additive manufacturing education under the auspices of the Samuel Ginn College of Engineering’s National Center for Additive Manufacturing Excellence.

Engineering students enrolled in a four-year Bachelor of Science program can earn a certificate in additive manufacturing by taking three related classes as technical electives, says NCAME Director Nima Shamsaei. Graduate students pursuing a doctorate in mechanical engineering can choose to complete their master’s thesis in additive manufacturing.

According to Shamsaei, undergraduate students are finding entry-level positions in additive manufacturing “very quickly” as companies seek to build out their staff in this area, while graduate students are better-prepared for more complex managerial roles. The university’s grad students also tend to be well known to the manufacturing community at large, he says, as a result of NCAME’s research and participation activities.

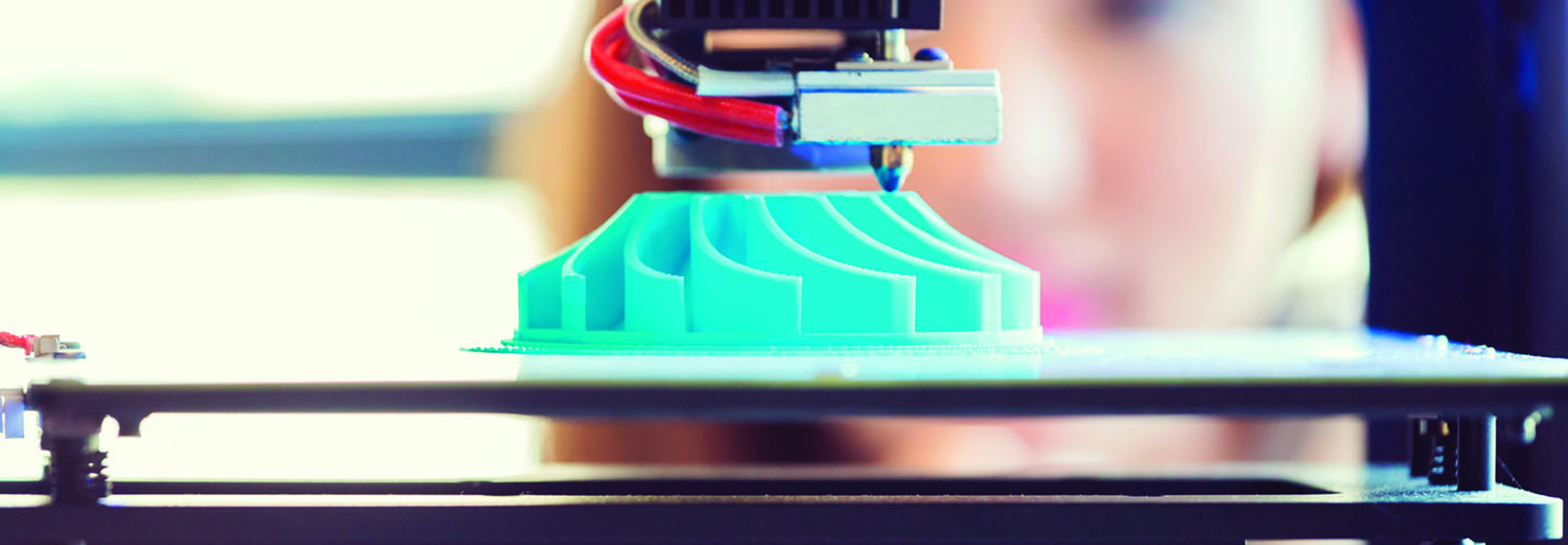

Leveraging solutions such as direct metal laser sintering systems, laser metal fusion machines and high-speed 3D additive machine tools, the Samuel Ginn College of Engineering provides a combination of educational and technological foundations designed to help students succeed in today’s rapidly changing manufacturing environment.

To meet the demand for additive manufacturing skills, other institutions offer two-year certificate programs to help speed the transition from classroom learning to real-world expertise.

At Iowa’s Kirkwood Community College, students spend four semesters and one summer developing key skill sets including product design, machining, welding and quality control. Graduates are equipped for entry-level careers such as a laser cutter operator, robotics engineer or CAD designer.

The college also offers a one-year training certificate in industrial robotics to help students enter the job market as quickly as possible.

While hands-on work with 3D printing in higher education helps bolster student skills, online programs have emerged to help streamline student success. Introductory courses from Purdue University in Indiana give students the fundamental knowledge necessary to jump-start their careers, while advanced certifications provide additive manufacturing insight for engineers and managers who already work in the industry and want to supplement their existing skills.

MORE FROM EDTECH: See how colleges can help close the additive manufacturing skills gap.

Additive Manufacturing Programs Evolve to Meet Industry Needs

As additive manufacturing diversifies across industry applications, colleges are keeping pace with a variety of curricular formats to meet market demands.

But what’s next for additive manufacturing degree and certificate programs? To ensure educational opportunities match employer expectations, curricula must align with industry advancements, including:

- Technology integration: As 3D printing technologies move into markets such as medical prosthetic development and custom-built automotive component creation, programs must stay current with up-to-date infrastructure and devices. As noted by Design News, while first-generation 3D printers helped improve design validation, prototyping and tooling improvements to boost productivity, the next iteration of additive manufacturing tools must leverage increased speed to enhance mass production.

- Enhanced specialization support: According to Shamsaei, Auburn University is developing specialized additive manufacturing degrees to reflect the evolution happening in the workforce. This specialization will help institutions scale their curricula as the market expands. For example, NCAME recently partnered with NASA to develop improved liquid rocket engines using additive manufacturing techniques. This work, along with other public-private partnerships, will help inform Auburn’s evolving educational opportunities.

- Increased industry collaboration: To ensure programs remain relevant, academic leaders must partner with industry leaders to develop student skills that match market requirements. With 52 percent of companies already facing a skills shortage in additive manufacturing, colleges need guidance from industry to help identify critical gaps.

Consider the recent launch of Siemens’ online additive manufacturing network, which offers an order-to-delivery collaboration platform that lets users facilitate order management, parts preparation and job scheduling. This industry evolution speaks to the need for dual-track student development: Undergraduates require both hands-on technology experience and the training necessary to deploy, manage and monitor emerging IoT networks that deliver additive manufacturing solutions at scale.

Additive manufacturing underpins the key advantage of contemporary industry: technologies that fundamentally shift design and development practices, giving companies both granular control of production output and on-demand adaptation to changing market conditions.

The result? Higher education curricula must align with evolving industry expectations to produce graduates that possess both technological expertise and targeted experience.