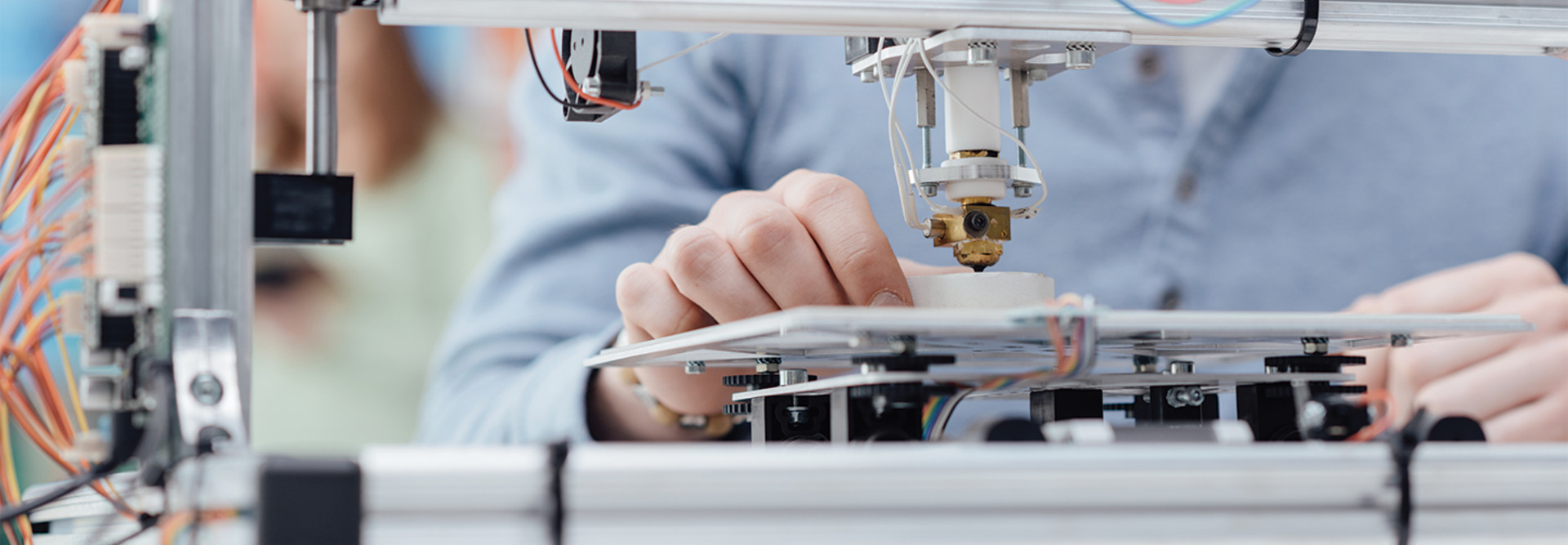

Hamilton County (Tenn.) Schools has put their 3D printers to work in recent weeks in support of frontline COVID-19 responders.

At the outset of the crisis, the district rounded up its digital fabrication resources in a single lab and has since digitally printed nearly 4,500 headbands to secure face shields for healthcare workers. “We want to educate future leaders who can be thoughtful and can work together to solve real-world problems. This is a great example of that,” says Jill Levine, the district’s chief of innovation and choice.

The district is not alone. Around the nation, K–12 schools have leveraged their 3D printers to help close critical shortages in personal protective equipment, or PPE.

Students at Camdenton High School in Missouri have used 3D printers to create hundreds of face shields for healthcare workers at a local hospital. West Ashley High in Charleston, S.C., is producing 3D-printed masks with HEPA filters to assist healthcare professionals, and Barboursville (W.Va.) Middle School has 3D printed over 600 masks.

MORE ON EDTECH: Learn about the classroom benefits of 3D printers.

Using 3D Printers with an Innovative Mindset

Hamilton County was deeply invested in 3D printing even before the recent pandemic. Three years ago, the district partnered with a local Volkswagen plant, tapping $1 million in state tax incentive money to create digital fabrication labs in 19 schools. (Five more district schools are set to launch similar labs this summer.)

“The innovative design-thinking mindset was already prevalent in our district,” Levine says. “One K–8 school has worked with people with disabilities to create prosthetic devices and tools that help them to work. One school has created a rearview mirror for bikes as a safety feature. Other schools have been making parts for musical instruments, things like 3D-printed reeds for reed instruments.”

When the need for PPE emerged, the district gathered all 73 of its 3D printers, including equipment from Dremel, to create a 3D printer farm at STEM School Chattanooga. Teachers volunteer their efforts in the open space — no more than eight at a time, for social distancing — and some share the fabrication process with students via Zoom for Education.

In addition to 3D printing the headbands, the district is also using its tools to laser-cut foam padding to ensure the plexiglass masks can be worn comfortably for many hours.

“We worked with local doctors to prototype the kinds of things they would be using, and we’ve heard feedback that the ones we are producing are more comfortable than the standard-issue ones,” Levine says.

3D Printing Protective Gear for Healthcare Workers

At Cleveland County (N.C.) Schools, educators are using MakerBot Replicator 5th Generation printers and two smaller MakerBot SKETCH Classroom machines to fabricate masks for healthcare workers.

“My mom is a nurse, and she was telling me how they have to wear the same masks day in and day out because they don’t have enough materials,” says Beverly Owens, an 8th-grade science teacher at Kings Mountain Middle School. “Then I started seeing the same thing in pictures from all over the country, and I realized just how big a problem this was.”

The school already had 3D printers on hand as an aid to classroom education. “I use it to print out things like fossil replicas that the students can use for different lab exercises,” Owens says.

When the COVID-19 crisis hit, she pulled down designs from the MakerBot design-sharing platform Thingiverse and has since printed over 400 pieces of PPE, including masks, face shields and ear guards to make masks more comfortable for long-term use.

“I’ve always felt that if you have the ability, then you have the responsibility,” she says. “I have these machines, I have the capability, and I am happy to do whatever I can to help.”

In Hamilton County, Levine says it took just two days to get her district’s 3D printers up and running in support of PPE production. The rapid repurposing of the technology reflects K–12’s inherent ability to shift on the fly, she says.

“Schools have to able to respond to crises,” she says. “It took us 48 hours to set this up and start producing, where businesses took five to six weeks to get up to speed. School districts are used to continually responding to new challenges and new problems. It makes us very nimble.”