5 Things to Learn from the First MakerBot Summit

3D printing, rising in popularity with every passing year, is really set to take off.

Global revenues for the 3D printing industry are expected to rise to $35.4 billion by 2020, market research and analysis firm IDC reports. And higher education is staking its claim in the industry.

MakerBot, the 3D printing giant, launched Innovation Centers — 3D printing labs— at universities across the country, starting with State University of New York at New Paltz in 2014.

In June, MakerBot hosted the inaugural MakerBot Innovation Center Summit, where leaders from 11 universities gathered in New York City to share their accomplishments, learn new policies and network their blog reports.

“The summit was held at the behest of our customers,” says Wallace Patterson, MakerBot’s global director of educational enterprise sales. “MakerBot only spoke once or twice. It was Innovation Center partners speaking to each other and addressing what was important to them.”

Here are some of the main takeaways from the summit.

1. Curriculum Integration Is Key

Before the Innovation Center leaders came together, Patterson says MakerBot asked them to identify what they were interested in learning about. Patterson said the universities were unanimously most interested in learning how to effectively integrate 3D printing technology into their coursework.

To meet this need, the summit featured a discussion panel with representatives from Innovation Centers explaining their curriculum,

According to Patterson, the biggest challenge in adding 3D printers to any curriculum is to use them to create a solution to a problem posed in the class, rather than dedicate the course solely to the technology.

Another panel discussed how they could apply their success to other parts of the university and explain to the administration how achievements in the 3D printing labs fit the framework of the course.

2. Leaders Are Hungry for 3D Printing Collaboration

As was the impetus for the summit, Patterson says Innovation Center leaders were eager to network.

“They’re hungry to share what they’ve learned with the others. [The leaders] are also very hungry to learn what the other innovation centers have gone through,” he says.

Several leaders presented their work formally, but Patterson says that the structured sessions were supplemented with lots of open time for informal “hallway conversations” to occur.

3. 3D Printing Labs Are All Unique

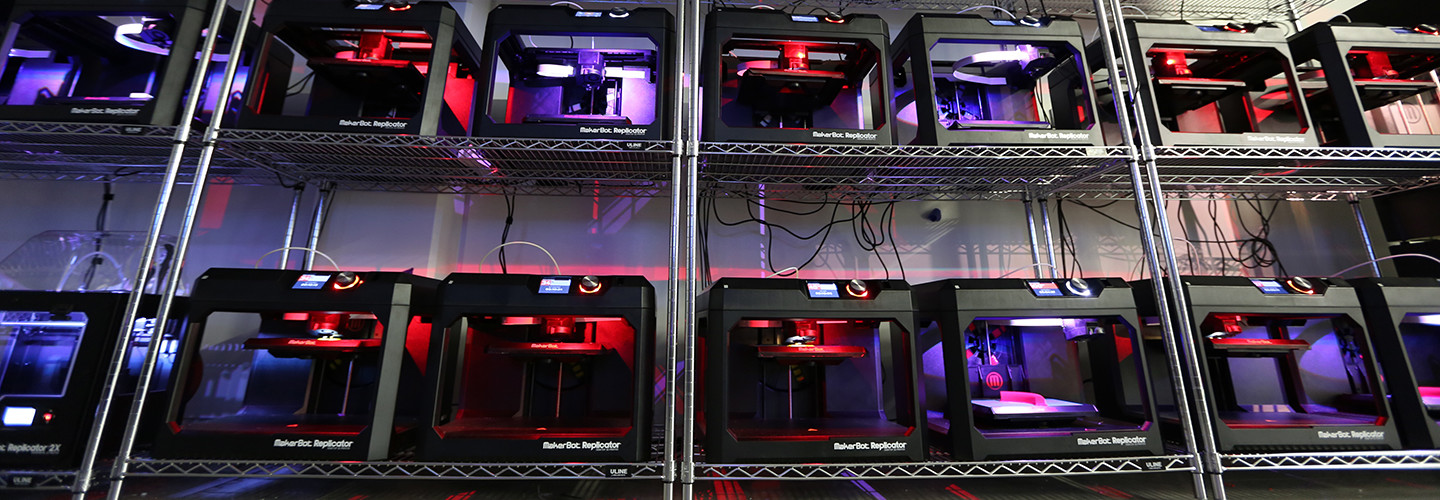

All Innovation Center labs come outfitted with 30 to 60 MakerBot 3D printers and share the same racking, software, training and installation. The similarities, however, often stop there.

“While the equipment is relatively identical, the application in each Innovation Center is quite different,” Patterson says.

From fashion design and art at Central Michigan University to the University of Maryland’s engineering lab, students from all disciplines are using MakerBot’s technology to advance their fields.

4. Labs Creating Partnerships Between Communities and Universities

Leaders from MakerBot’s first Innovation Center at SUNY New Paltz were on hand to discuss their strides in manufacturing, Patterson says. Along with the lab, the school created the Hudson Valley Advanced Manufacturing Center (HVAMC), which facilitates partnerships between the university and community K–12 educators with courses and training. But, more importantly, the HVAMC works with local businesses.

“[SUNY New Paltz] concentrates equipment, knowledge and expertise at the university and they pull the entrepreneurs to them,” Patterson says. “They have started essentially an in-house internship program. A lot of these entrepreneurs couldn’t afford to take on a full time intern otherwise.”

5. The ‘A’ in STEAM Is a Huge Focus

Another highlight of the summit was the awarding of the first MakerBot Innovator Award, which was given to Florida International University’s College of Communication, Architecture + The Arts. Their off-campus creative space at the Miami Beach Urban Studios is high among all the Innovation Centers in terms of using the most plastic filament, Patterson says.

Their 3D printing lab is used for purely art and architecture design, and they’ve created everything from experimental musical instruments to architectural models and even a spill-free beverage holder, the MakerBot Summit blog reports.

“It’s a bit counterintuitive because 3D printing is a well-known engineering tool, but [FIU] has art history professors using their Innovation Center,” he says.